A Premier Manufacturer of Complex Composite Components and Assemblies

VISIT OUR WEBSITE

Getting your best ideas off the ground

With expertise in manufacturing a wide array of complex composite components and major assemblies, Qarbon Aerospace reliably delivers on the most demanding requirements.

Defense

Learn More

Qarbon Aerospace plays an integral role in the US defense industry, specializing in the production of crucial military aircraft structures to exact specifications. Our facilities in Texas and Georgia support various defense programs, including the manufacture of completed wings for Northrop Grumman’s HALE, Pratt & Whitney’s F135 engine duct, Boeing’s V-22 empennage and T-7A metallic structures. Our commitment to precision and reliability is unwavering in serving the US defense forces.

Space

Learn More

As a strategic partner and supplier to the leading companies in the field of space travel, Qarbon Aerospace leverages our extensive expertise in manufacturing major structures such as wings and fuselages to play a crucial role in the development and production of next-generation space vehicles. We take great pride in our involvement in manufacturing the wing and fuselage for the Virgin Galactic Delta Spaceship, providing fully integrated structures that interface with mating structures. Additionally, our advanced thermoplastic technologies in welding and ground breaking electrothermal heating provide the space industry with innovative solutions that are unique and pioneering in addressing the

challenges faced within the harsh environment of space.

Commercial and Business Aviation

Learn More

Qarbon Aerospace has a distinguished history of manufacturing significant structures and components for leading OEMs such as Boeing,

Airbus, and Gulfstream. Our high-quality, build-to-print composite parts and structures are utilized by these major OEMs. Each part is precision-engineered and meticulously prepared for safe and reliable operation on commercial aircraft worldwide.

Advanced Air Mobility (AAM)

Learn More

Qarbon Aerospace is at the forefront of shaping the future of Advanced Air Mobility (AAM) through our ongoing development of advanced thermoplastic technologies, which enables high-rate production necessary for the growing AAM market. Our expertise extends to patented processes in induction welding and our innovative all-composite electrothermal ice protection system HELIOS™. These technologies not only enhance performance but also ensure reliability and durability in demanding AAM environments.

Manufacturing Capabilities

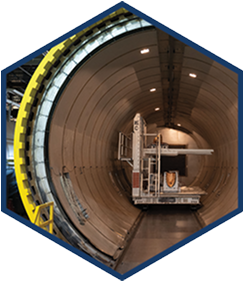

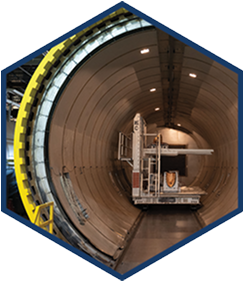

Automated and Hand Layup

Our automated layup process incorporates advanced equipment such as 5-axis and 3-axis Automated Tape Laying, 5-axis Automated Fiber Placement capable of laying down both Thermoset and Thermoplastic materials, an Automated Stringer Machine, SQRTM, and Fiber Tow Placement machines. Furthermore, our climate-controlled areas for hand layup adhere to stringent air quality standards and utilize state-of-the-art technology such as overhead ply projection systems and debulk stations.

High-Temp Composites

Expertise in material systems with service temperatures up to 700°F (371°C), Autoclaves up to 800°F, pressure up to 200 PSI, and ovens up to 1000°F.

Major Structural Assembly

With a rich history in manufacturing significant structural assemblies, Qarbon Aerospace possesses the expertise and experience to produce composite and metallic assemblies, including wings, empennage, nacelles, and fuselage components for both fixed-wing and rotary aircraft.

Systems Integration

Qarbon Aerospace exhibits extensive expertise in systems integration across wings, fuselages, and empennage assemblies. Critical tests are performed in-house on precisely installed hydraulic, electrical, and fuel systems to ensure seamless coordination and optimal performance of these integrated systems within aerospace structures.

Thermoplastic Technologies

Induction Welding

LEARN MORE

Qarbon Aerospace’s advanced fusion-joining technology for thermoplastic structures eliminates the need for fasteners in assemblies, reducing weight and manufacturing costs significantly.challenges faced within the harsh environment of space.

Qarbon Differentiators

- Dissimilar thickness joints without the need for a susceptor

- One-side-only access enables closed box assemblies and reduced tooling costs

- Focused heat only where it’s needed

- Scalable for large primary structure

- Works with commercially available materials

- Weld rates demonstrated up to .75 m/min

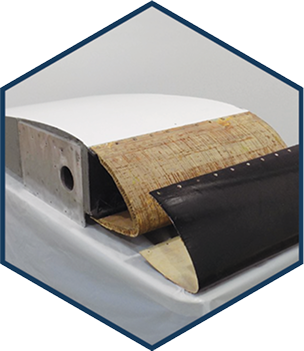

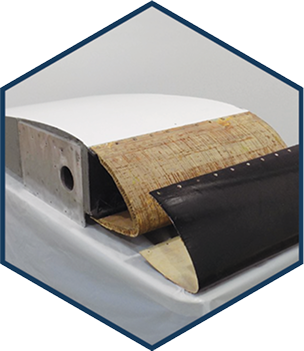

Thermoplastic Icing Protection System

LEARN MORE

Qarbon’s HELIOS™ electrothermal icing protection systems are designed for both, installation on existing aircraft, as well as new production next generation aircraft, delivering safety improvements, weight savings and maintenance reductions.

Qarbon Differentiators

- Direct replacement for legacy systems

- Multi-zone system optimized for low power consumption during de-icing

- Low power requirements

- Weight savings vs pneumatics

- Significant maintenance reduction

- Enables electrification of aircraft

- Painted or Polished leading edge capable

Locations

Large Complex Structural Assembly 123-acre site with 772,000 ft² of manufacturing space, just minutes from DFW International Airport.

Major Programs

- HALE Integrated Wing

- Virgin Galactic Delta Class Wing & Fuselage

- V-22 Integrated Empennage

- F135 Engine Compressor Duct

- G600 Horizontal Tail

- T-7A Wing, Empennage & Forward Fuselage

- 525 Relentless Fuselage

- 767 Aft Pressure Bulkhead

Premier Composite Manufacturing 165-acre site with 650,000 ft² of manufacturing space, near Atlanta, GA.

Major Programs

- 787 Frames, Longerons & Stringers

- 777 Flaps, Spoilers and Ailerons

- 767 Wing Center Section Keel Beam & Seal

- Depressor panels

- KC-46A Tanker Engine Cowls

- G650 Spoilers, FTE,

- Winglets & Cove panels

- HALE Wing Structure

- V-22 Sponsors & MLGD, Ramp & Door Assemblies & Wiper Fairings

- Embraer E-2 Rudder & Elevator

Best-Cost Complex Composite Components 12-acre site with 150,000 ft² of manufacturing space, near Suvarnabhumi International Airport.

Major Programs

- Fan Case and Acoustic Liners for major Trent and Pearl Engines

- A320 family Flap Detail Parts

- A320 family Vertical Tail Leading Edge and Fairings

- A330 family Vertical Tail Trailing Edge and Fairings

- A330 family Wing Leading Edge Composite Panels

- A350 family Wing-to-Body Fairing Composite Details

- A350 family nsBB Composite Details

- 787 Pylon Composite Fairings and Detail

Contact Qarbon Aerospace to take your ideas to new heights.

Mike Lee

VP, Business Development

Contact.Us@QarbonAerospace.com

300 Austin Blvd. Red Oak TX, 75154

817-881-5685

A Premier Manufacturer of Complex Composite Components and Assemblies

VISIT OUR WEBSITE

Getting your best ideas off the ground

With expertise in manufacturing a wide array of complex composite components and major assemblies, Qarbon Aerospace reliably delivers on the most demanding requirements.

Defense

Space

Commercial and Business Aviation

Advanced Air Mobility (AAM)

Manufacturing Capabilities

Automated and Hand Layup

Learn More

Our automated layup process incorporates advanced equipment such as 5-axis and 3-axis Automated Tape Laying, 5-axis Automated Fiber Placement capable of laying down both Thermoset and Thermoplastic materials, an Automated Stringer Machine, SQRTM, and Fiber Tow Placement machines. Furthermore, our climate-controlled areas for hand layup adhere to stringent air quality standards and utilize state-of-the-art technology such as overhead ply projection systems and debulk stations.

High-Temp Composites

Learn More

Expertise in material systems with service temperatures up to 700°F (371°C), Autoclaves up to 800°F, pressure up to 200 PSI, and ovens up to 1000°F.

Major Structural Assembly

Learn More

With a rich history in manufacturing significant structural assemblies, Qarbon Aerospace possesses the expertise and experience to produce composite and metallic assemblies, including wings, empennage, nacelles, and fuselage components for both fixed-wing and rotary aircraft.

Systems Integration

Learn More

Qarbon Aerospace exhibits extensive expertise in systems integration across wings, fuselages, and empennage assemblies. Critical tests are performed in-house on precisely installed hydraulic, electrical, and fuel systems to ensure seamless coordination and optimal performance of these integrated systems within aerospace structures.

Thermoplastic Technologies

Induction Welding

LEARN MORE

Qarbon Aerospace’s advanced fusion-joining technology for thermoplastic structures eliminates the need for fasteners in assemblies, reducing weight and manufacturing costs significantly.challenges faced within the harsh environment of space.

Qarbon Differentiators

- Dissimilar thickness joints without the need for a susceptor

- One-side-only access enables closed box assemblies and reduced tooling costs

- Focused heat only where it’s needed

- Scalable for large primary structure

- Works with commercially available materials

- Weld rates demonstrated up to .75 m/min

Thermoplastic Icing Protection System

LEARN MORE

Qarbon’s HELIOS™ electrothermal icing protection systems are designed for both, installation on existing aircraft, as well as new production next generation aircraft, delivering safety improvements, weight savings and maintenance reductions.

Qarbon Differentiators

- Direct replacement for legacy systems

- Multi-zone system optimized for low power consumption during de-icing

- Low power requirements

- Weight savings vs pneumatics

- Significant maintenance reduction

- Enables electrification of aircraft

- Painted or Polished leading edge capable

Contact Qarbon Aerospace to take your ideas to new heights.

Mike Lee

VP, Business Development

Contact.Us@QarbonAerospace.com

300 Austin Blvd. Red Oak TX, 75154

817-881-5685